Mining Companies And Current Advancements

BHP

In the Escondida copper mine in Chile, the company trialed smart caps which analyzed driver brain waves to measure and act on fatigue. This was integrated into over one-hundred-and-fifty trucks to boost productivity and increase safety.

They are also using AI in automating decision making. For example, Mining Area C in Western Australia Iron Ore is using a system that selects which crusher trucks they should use. This cuts down a lot of time spent on making decisions and also increases efficiency since decisions are generally better than humans.

BHP is also deploying autonomous hauling vehicles at their Jimblebar Iron Ore mine and through this change has reduced costs by roughly 20%.

Vale

Vale is using AI in several areas with Advanced Analytics and is saving big as a result. At Salobo copper mine in Para, Brazil, there was a 30% increase in the lifespan of haul truck tires in one year which saved the company $5 million. This same technique is being applied in other mines and other truck parts including engines and fuel consumption.

Vale also uses AI to predict rail fractures which is helping to reduce the occurrence of fractures by up to 85%. This can save Vale $7 million per year. In total, the company expects to save around $26 million in 2018 from these changes alone.

Goldcorp

Goldcorp recently partnered with IBM to put their smart technology towards exploration. IBM Watson services are being used to analyze drilling reports, geological survey data and more in determining which areas to explore and to quickly locate high-value targets.

In addition to the other beenfits mentioned before, this will also lead to a smaller impact on the environment.

Current Innovations

- Goldspot Discoveries is applying AI in mineral exploration as well. Recently they predicted 86% of existing gold deposits in the Canadian Abitibi gold belt, which was achieved using geological, topographical and mineral data from only 4% of the surface area.

- Motion Metrics’ Fragmentation Analysis is using AI to more accurately measure rock fragmentations. This method of data collection can provide valuable feedback to the engineers, increase productivity, and even optimize teeth changeouts by monitoring teeth wear.

- Tomra has developed mineral and ore sorting equipment which uses sensors to separate valuable mineral ores from waste rock. From things like fast-paced laser sorting and product recognition.

- PETRA Data Science offers technology that uses machine learning AI to enable automated ore fragmentation assessment. Their algorithms use data collected from 3D mapping to assess ore fragmentation within one minute as opposed to manual processing which can take more than an hour to complete.

Looking Forward

It is clear that automation and use of Ai and Machine Learning can significantly help save costs, increase efficiency and have tons of other benefits for companies. What’s holding us back is data and having really good, and a large amount of it. However, companies are working on scaling the use of AI in Machine Learning in Mining and with big data becoming a huge industry we can start seeing more use of AI in the mining industry. One that is completely changing from what we’ve traditionally known it to be.

Autonomous vehicles and drillers

While many of us have been focused on the progress Uber, Google and Tesla have made with autonomous vehicles many people don’t realize that Rio Tinto (one of the worlds largest metals and mining corporations) has already been using autonomous haul trucks that can carry 350 tons and operate totally independently since 2008. These trucks have been so effective that they’ve reduced fuel use by 13 percent and are also much safer to operate.

Safety

AI can help Machine Learning in Mining engineers and workers prevent accidents and injuries on the job. If enough high-quality data can be collected, we can predict failures that can not only affect production but also be harmful or fatal to any workers nearby.

In addition to predicting failures, we can also use Ai to predict other potential hazards by analyzing patterns in events. This is really useful because the environment in mining can affect the operation and lifespan of equipment, varies greatly depending on the location.

But we can also do more than just predict when equipment might fail or which hazards can present themselves using AI. We can also constantly survey the health and performance of equipment which is important in eliminating surprise failures and dangers to workers.

Mining Companies Using AI, Machine Learning And Robots

It was just a few years ago when Artificial Intelligence (Ai) was a newly emerged idea that was too technically advanced for people to predict how it could impact the world. Fast forward to 2019 and things have definitely changed. It’s become a real game changer for countless industries including major players in the Machine Learning in Mining.

Mining is an industry where improving efficiency and productivity is essential for profitability, as small improvements in yields, speed and efficiency can make an extraordinary impact.

The mining industry employs a lot of individuals — just 670,000 Americans are employed in the quarrying, mining and extraction sector. Our current methods are just not effective and can result in a lot of loss which is detrimental since mining can impact nearly every other industry since it provides the raw materials for virtually every other aspect of the economy.

Mineral exploration

The current mineral exploration process is basically massive amounts of data in the form of soil samples, chip samples, geochemistry, drill results, and assay results. Each drill hole is a tiny snapshot of the processes that form the earth.

A single drill hole can create 200 megabytes of data and if there are more drill holes with other types of information, an exploration project can produce terabytes of data. If you wanted to compare your one project to hundreds of others to find the best insights, this becomes difficult since the amount of data is crazy.

All of these data points are so important though because using this data we can find new mineral deposits, but to sort through them is too much for even an entire team of capable geologists.

Using Machine Learning, we can train computers to spot the areas showing similar patterns to past discoveries.

HOW DOES IT WORK HERE

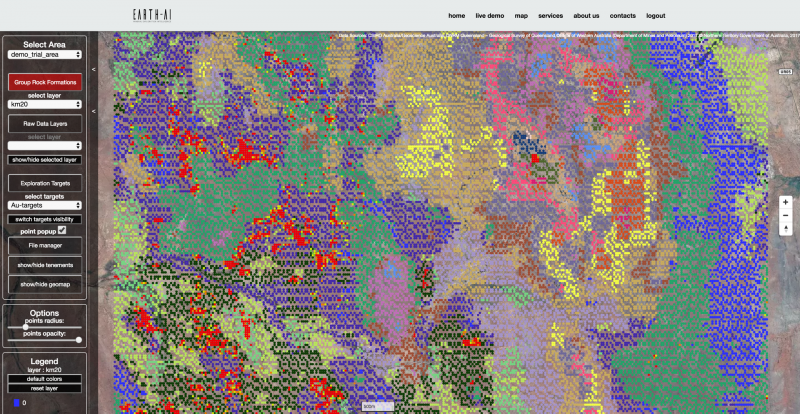

EARTH AI is helping mineral explorers identify promising areas. They do this by analyzing data from multiple sources and using a machine learning algorithm to identify areas where minerals are likely to be found. 47 layers of remote sensing and geophysical data are analyzed at once by machine learning — they can highlight ore bodies and alteration haloes as well as map out hard rocks and regolith with extreme detail.

Artificial intelligence and machine learning can help mining companies find minerals to extract. Some companies are already working on this. Goldspot Discoveries Inc. is a company that aims to make finding gold more of a science than art by using machine learning. Another company, Goldcorp and IBM Watson are collaborating to use artificial intelligence to review all the geological info available to find better drilling locations for gold in Canada.